Application of disc rake bearings

2023-04-11

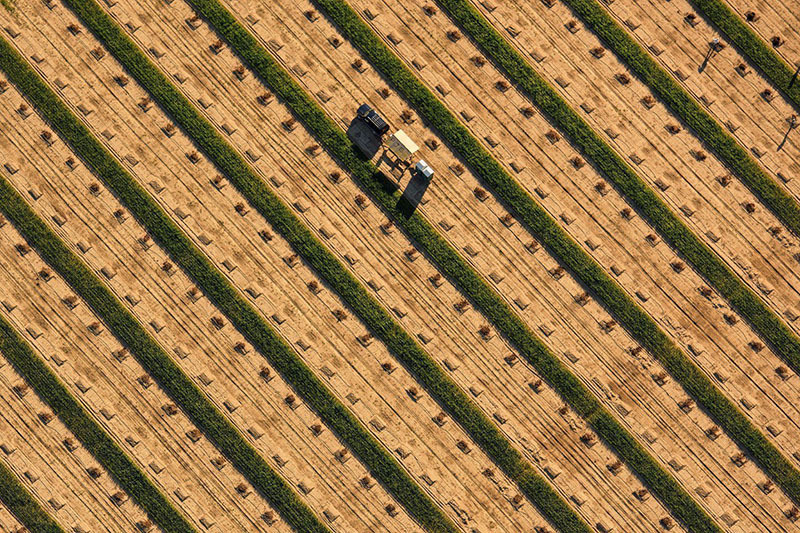

Whether cultivating soil or mowing grass, a disc rake must remove heavy and laborious soil, dust, and more. In working condition, the disc rake bearing must come into contact with these substances and withstand both heavy and impact loads. During the flushing process, the bearing seals must be kept free of water and detergent, and lubricants must not leak out.

VIEW MORE

2023-04-11

The movement of lubricating grease in bearings can be roughly divided into two stages: the running in period and the balance period.

During the running in period of the bearing, excess lubricating grease accumulates in the cavity of the cage or bearing, and accumulates on the periphery of the rolling element. If there is excessive lubricating grease, it will cause the temperature of the bearing to rise, and even burn (destroy) the bearing.

VIEW MORE

Assembly Techniques for Different Agricultural Machinery Parts

2023-04-11

The proper assembly of agricultural machinery parts is related to the length of time for smooth operation of agricultural machinery. In order to ensure good long-term use of agricultural machinery, the assembly work of agricultural machinery parts must be done well. The following are assembly techniques for some agricultural machinery components.

VIEW MORE

What are the supporting accessories for bearings?

2023-04-11

Bearings are an indispensable part of mechanical equipment components, and the accessories of bearings are also an indispensable part of bearings. What are the supporting accessories of bearings? Based on our understanding of bearing knowledge, the main accessories for bearing accessories include: tightening sleeve, withdrawal sleeve, locking nut, locking device, bearing seat, thrust ring, etc.

VIEW MORE

What are the effects of ineffective lubrication of bearings

2023-04-11

Rolling bearing is a kind of mechanical element that is widely used in mechanical transmission. The movement condition is mainly rolling and sliding friction. Because friction will cause local thermal deformation, accelerate the wear of part surface, resulting in increased operating error, and even make the spindle scrapped. The causes of bearing failure are often multifactorial, and all factors affecting the design and manufacturing process are related to bearing failure. Analysis of the causes of bearing damage shows that about 40% of bearing damage is related to poor lubrication.

VIEW MORE